Machine Condition Monitoring & Predictive Maintenance

Space-grade measurement technology brought into machine condition-based monitoring. Accurate, highly reliable, easy to use and cost-effective real-time condition monitoring solution.

Our condition-based monitoring solution is ideal for any kind of rotating machinery such as electric motors, gearboxes, pumps, etc.

Space-grade measurement technology brought into machine condition-based monitoring. Accurate, highly reliable, easy to use and cost-effective real-time condition monitoring solution.

Our condition-based monitoring solution is ideal for any kind of rotating machinery such as electric motors, gearboxes, pumps, etc.

Condition Based Monitoring (CBM)

Machine condition monitoring (or condition-based monitoring - CBM) is the process of monitoring condition in machinery while in operation (vibration, temperature, etc.) in order to identify a significant change which is indicative of a developing fault or malfunction. It is a major component of predictive maintenance.

Dewesoft is a leading provider of high-end data acquisition systems (DAQ), DAQ software covering test and measurement applications in different industries. Dewesoft offers solution totally distributed and easy to use machine condition monitoring systems for condition-based monitoring.

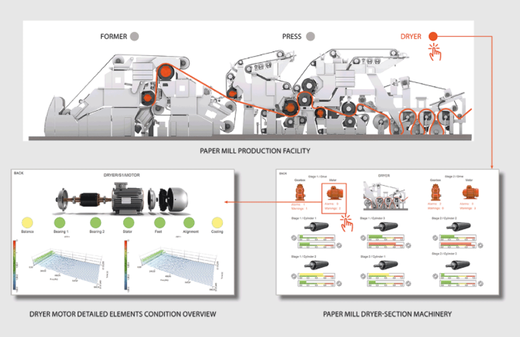

The solution suits applications such as permanent condition-monitoring of gearboxes, fans, motors, blowers and any other rotating machinery in automotive, mining, pulp, paper, iron, steel, chemical, cement, old and gas, facility management and power generation.

This cost-effective solution enables production facility owners to start permanent monitoring of critical equipment with high ROI. Ultimately, it helps reducing production downtime, lowering maintenance and repair costs and increasing company profitability.

Machine condition monitoring (or condition-based monitoring - CBM) is the process of monitoring condition in machinery while in operation (vibration, temperature, etc.) in order to identify a significant change which is indicative of a developing fault or malfunction. It is a major component of predictive maintenance.

Dewesoft is a leading provider of high-end data acquisition systems (DAQ), DAQ software covering test and measurement applications in different industries. Dewesoft offers solution totally distributed and easy to use machine condition monitoring systems for condition-based monitoring.

The solution suits applications such as permanent condition-monitoring of gearboxes, fans, motors, blowers and any other rotating machinery in automotive, mining, pulp, paper, iron, steel, chemical, cement, old and gas, facility management and power generation.

This cost-effective solution enables production facility owners to start permanent monitoring of critical equipment with high ROI. Ultimately, it helps reducing production downtime, lowering maintenance and repair costs and increasing company profitability.

Why is Permanent Monitoring Needed?

Using condition monitoring techniques is the only way to understand the condition of your machines in detail and to be able to perform the right maintenance at the right time.

Example: Imagine how vulnerable would people be without the sensing ability?

" US Department of Energy: The efficiencies of mechanical equipment, in general, can be increased typically 10 to 15 percent by permanent condition monitoring and scheduled maintenance."

Using condition monitoring techniques is the only way to understand the condition of your machines in detail and to be able to perform the right maintenance at the right time.

Example: Imagine how vulnerable would people be without the sensing ability?

" US Department of Energy: The efficiencies of mechanical equipment, in general, can be increased typically 10 to 15 percent by permanent condition monitoring and scheduled maintenance."

Parameters & Fault Detection

What Parameters Can We Measure & Observe?

Temperature

Vibration

Strain

Pressure

Rotational Speed

Force

What Faults Can We Detect?

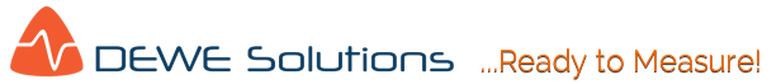

Bearing Faults

Overheating

Shaft Unbalance

Detached Mounting

Gear-Tooth Failure

Load Misalignment

Stator Eccentricity

Other Machine Catastrophic Failures

What Parameters Can We Measure & Observe?

Temperature

Vibration

Strain

Pressure

Rotational Speed

Force

What Faults Can We Detect?

Bearing Faults

Overheating

Shaft Unbalance

Detached Mounting

Gear-Tooth Failure

Load Misalignment

Stator Eccentricity

Other Machine Catastrophic Failures

Distributed Hardware

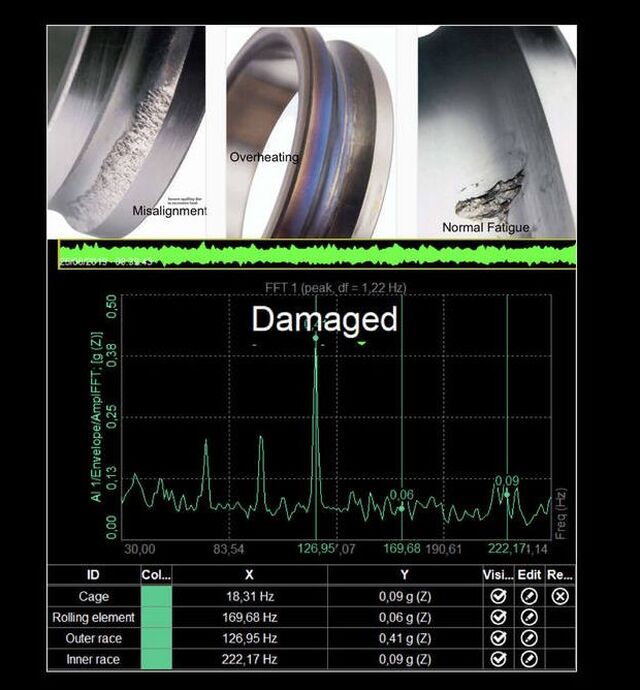

The latest Machine Condition Monitoring solution introduced is the Dewesoft IOLITEd-2xASI, a device with two analog sensor interface channels and one tacho specially designed to work with Dewesoft ASI-1xVIB-50g, a 10 kHz vibration and temperature sensor.

IOLITEd-2xASI: Data acquisition device with 2 analog input channels (with 40 kS/sec sampling speed per-channel) for interfacing 2 Dewesoft ASI-1xVIB-50g vibration probes and 1 digital input channel for connecting an RPM sensor (tacho).

ASI-1xVIB-50g: Single axis high bandwidth (10 kHz) and low noise vibration sensor probe which also includes a temperature sensor and 3-axial low speed accelerometer for orientation identification.

Benefits: The solution is designed for applications where distributed measurements of limitless numbers of perfectly synchronized vibration and temperature measurements are of the essence and where cost plays a significant role. Fast and easy mounting of devices is facilitated by using RJ45 connectors. The solution is bringing the DAQ device very close to the sensor eliminating long analog cables and thus reducing noise pick-up and cost.

The latest Machine Condition Monitoring solution introduced is the Dewesoft IOLITEd-2xASI, a device with two analog sensor interface channels and one tacho specially designed to work with Dewesoft ASI-1xVIB-50g, a 10 kHz vibration and temperature sensor.

IOLITEd-2xASI: Data acquisition device with 2 analog input channels (with 40 kS/sec sampling speed per-channel) for interfacing 2 Dewesoft ASI-1xVIB-50g vibration probes and 1 digital input channel for connecting an RPM sensor (tacho).

ASI-1xVIB-50g: Single axis high bandwidth (10 kHz) and low noise vibration sensor probe which also includes a temperature sensor and 3-axial low speed accelerometer for orientation identification.

Benefits: The solution is designed for applications where distributed measurements of limitless numbers of perfectly synchronized vibration and temperature measurements are of the essence and where cost plays a significant role. Fast and easy mounting of devices is facilitated by using RJ45 connectors. The solution is bringing the DAQ device very close to the sensor eliminating long analog cables and thus reducing noise pick-up and cost.

Condition Monitoring Software

Dewesoft machine condition monitoring software is unique on the market. It combines PC Client software with in-depth machine condition analysis features, relevant for PdM expert engineers, a high-level Web-based software layer with an overview of the machinery state, appropriate for quick decision making and Historian time-series database for permanent storage of the data.

Dewesoft machine condition monitoring software is unique on the market. It combines PC Client software with in-depth machine condition analysis features, relevant for PdM expert engineers, a high-level Web-based software layer with an overview of the machinery state, appropriate for quick decision making and Historian time-series database for permanent storage of the data.

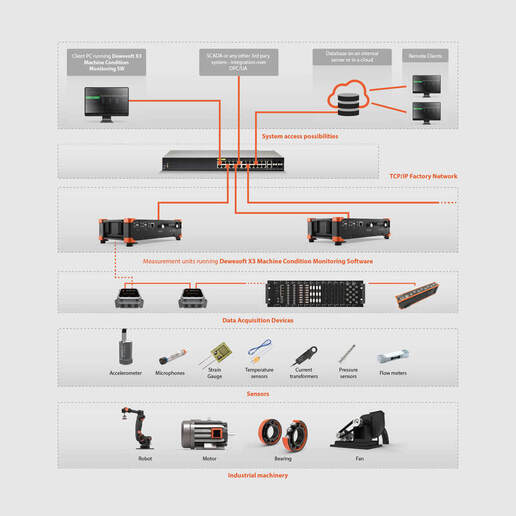

System Architecture

Dewesoft data acquisition systems, with its wide range of analog and digital inputs, offer support for almost any kind of 3rd party sensor. Digital and analog output devices provide the ability to drive actuators or switches.

All EtherCAT compatible devices (IOLITE, KRYPTON) can be connected into the same network giving the possibility to build a virtually unlimited channel chain by using a single cable delivering power, synchronization and data. The whole EtherCAT chain is synchronized to 1µs no matter the distance. Node-node distances can be up to 100m.

All the raw data from data acquisition devices are collected and processed by measurement units running the Dewesoft Machine Condition Monitoring software. Processed data is sent over the TCP/IP network to the factory server. Data can be accessed and viewed on the client PC or stored in the time series database (Historian) and served to SCADA systems or Cloud Software using standard interfaces such as OPC/UA or XCP to truly support Industry 4.0 applications.

Dewesoft data acquisition systems, with its wide range of analog and digital inputs, offer support for almost any kind of 3rd party sensor. Digital and analog output devices provide the ability to drive actuators or switches.

All EtherCAT compatible devices (IOLITE, KRYPTON) can be connected into the same network giving the possibility to build a virtually unlimited channel chain by using a single cable delivering power, synchronization and data. The whole EtherCAT chain is synchronized to 1µs no matter the distance. Node-node distances can be up to 100m.

All the raw data from data acquisition devices are collected and processed by measurement units running the Dewesoft Machine Condition Monitoring software. Processed data is sent over the TCP/IP network to the factory server. Data can be accessed and viewed on the client PC or stored in the time series database (Historian) and served to SCADA systems or Cloud Software using standard interfaces such as OPC/UA or XCP to truly support Industry 4.0 applications.